Equipment Manufacturer's New $9 Million Press Line Doubled Production and Improved Energy Efficiency by 70%

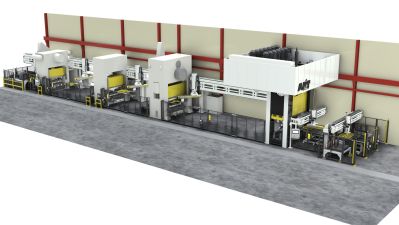

Bobcat Company, manufacturer of compact equipment, is increasing its production capacity at its Gwinner, North Dakota, USA facility, with AP&T's help. A new tandem press line, which recently began production, is expected to more than double press production capabilities, reduce energy consumption, lower noise levels and improve complex forming for sheet metal parts.

As a leading manufacturer of compact equipment since 1958, Bobcat has a proud legacy of innovation and a reputation based on delivering smart solutions to customers' toughest challenges.

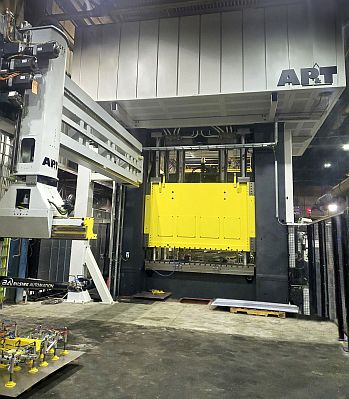

Bobcat's new production line in Gwinner, North Dakota, USA includes AP&T's energy-efficient servohydraulic press and automation equipment.

Headquartered in West Fargo, North Dakota, Bobcat is backed by the support of a worldwide network of independent dealers and distributors, Bobcat offers an extensive line of compact equipment, including loaders, excavators, compact tractors, utility products, telehandlers, mowers, attachments, implements, parts, and services.

Due to increasing demand for Bobcat equipment, the company recently purchased a new, highly automated tandem press line in an effort to double production.

"This investment will provide us with new capabilities and efficiencies in our metal stamping operations, and it also aligns with our commitment to innovation, sustainability and continued investments in our manufacturing footprint," said Mike Ballweber, president of Doosan Bobcat North America.

VIDEO: New servo hydraulic press by AP&T

The new line includes AP&T's energy-efficient servohydraulic press and automation. The assignment also includes line integration, operator training and support.

AP&T's servohydraulic press is 70% more energy efficient than a conventional AP&T hydraulic press. Photograph: Bobcat.

"Bobcat is one of the first companies in North America to invest in the future by implementing this automated solution using our new press technology," said Dr. Christian Koroschetz, chief sales officer of AP&T Group. "This investment also supports Bobcat's interest in pursuing sustainable, energy-efficient manufacturing solutions."

Servohydraulic Press, Boosting Energy Efficiency

The new AP&T servohydraulic press is 70% more energy efficient than a conventional AP&T hydraulic press. The press also provides increased productivity and superior forming capabilities, which enables the pressing of more intricate and complex designed parts, along with shorter cycle times.

Bobcat first became aware of the new press technology through a relationship with Wisconsin-based TCR Integrated Stamping Systems, a leading equipment manufacturer consultant and system provider for the metal forming industry.

"While visiting AP&T in Sweden, I was introduced to their latest automation breakthrough and knew it would provide a significant advancement for Bobcat. In addition, AP&T also demonstrated their new servohydraulic technology. Its unique capabilities had clear application for the Gwinner facility and is consistent with Bobcat's sustainability goals," said Todd Wenzel, president of TCR.

In addition to the energy being utilized in an effective manner, the servo hydraulic press also offers several other environmental advantages. The noise level is very low and the press is designed to be easily recyclable.

For AP&T North America, the commissioning of the new line is an important milestone in a successful collaboration.

"Bobcat has bestowed enormous trust in us and we will do our best to maintain it in our role as One Responsible Partner®," says Troy Hamilton, regional sales manager, AP&T North America.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::